Sport Display Recalibration – ECM Titanium tuning tips

Sport Display Recalibration – ECM Titanium tuning tips

ECM TITANIUM – Drivers

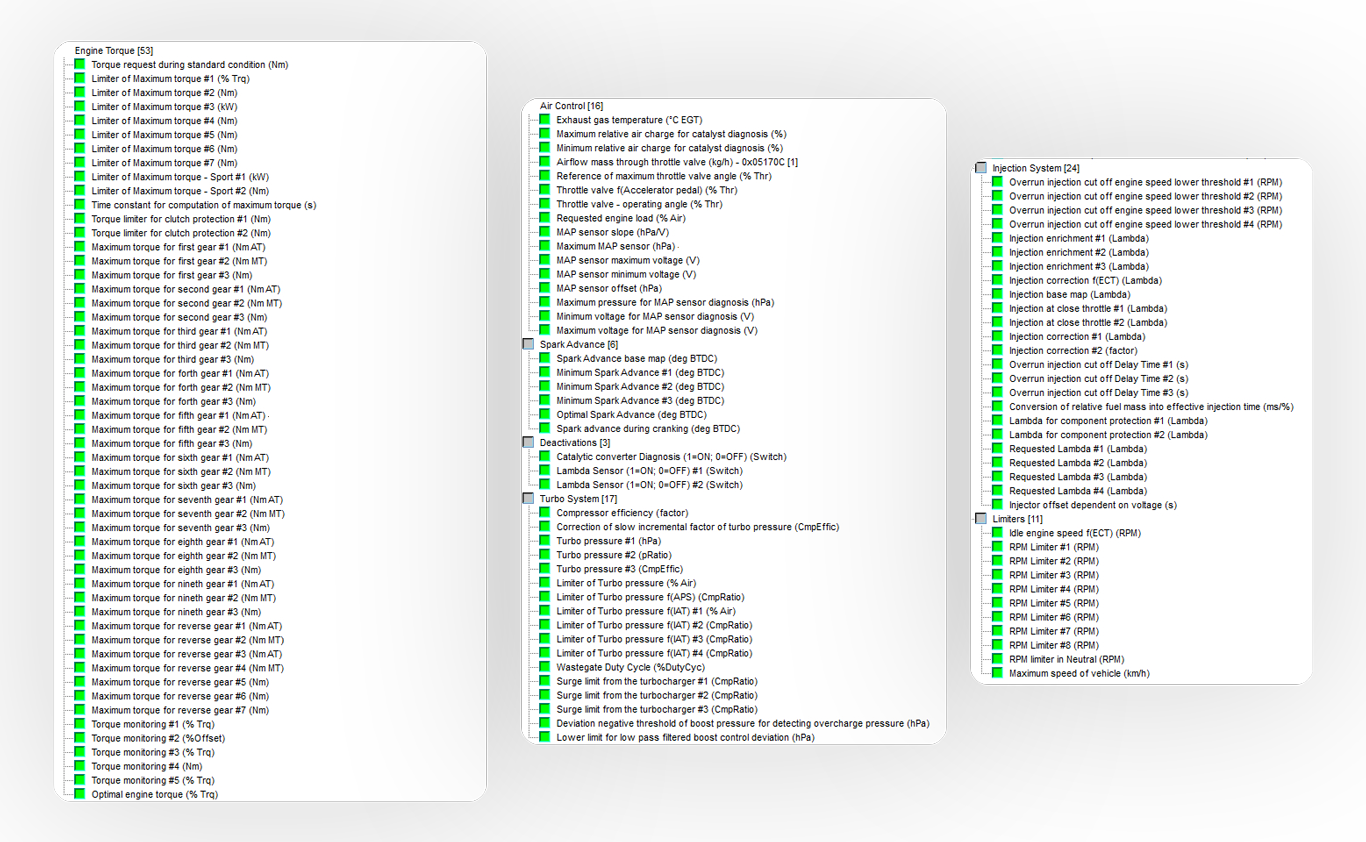

The Alientech team that deals with the Drivers update focused on the Bosch ME17.3.0 equipped on the cars of the FCA group. Intervene on the right maps and find out what you will be able to do thanks to ECM Titanium.

The ME17.3.0 is the management that mainly equips the 1.4 T-Jet engine, the “small” turbocharged engine developed by the Fiat group and mainly used on the sporty Abarth models.

It’s the most tuned engines, with a very wide possibility of mechanical modifications and a very high potential, especially if we consider his small displacement

ME17.3.0

ABARTH

ALFA ROMEO

FIAT

Thanks to its versatility and to the quantity of preparations that are made on this engine, during the massive update phase, the focus of the Drivers development team was in particular on the management maps of the injection cut-off in release, rescaling of sensors and injectors and much more.

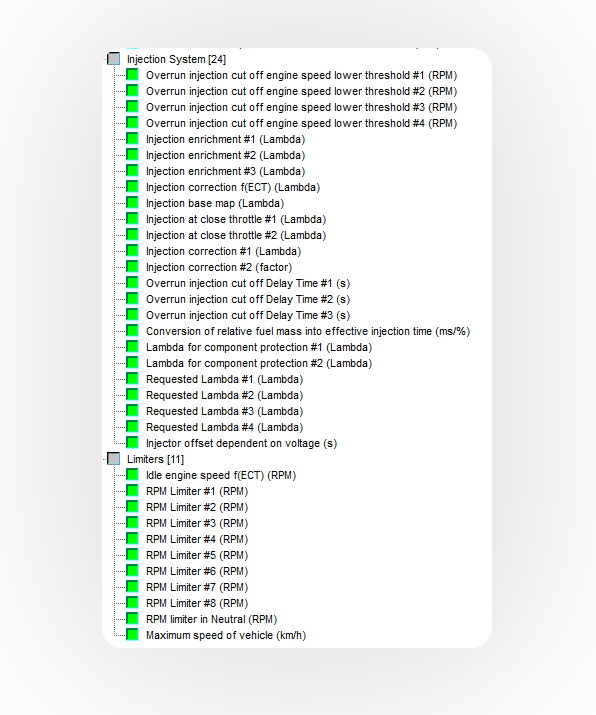

There is now the possibility of managing the injectors by intervening in a specific manner on the maps “fuel map conversion in actual injection time” and “Offset of the injector depending on the voltage”. These two maps allow the correct information to be given to the engine management on how many cc of fuel the installed injector is able to inject at a certain pressure in the supply circuit. We will therefore have the possibility to correctly manage oversized injectors when installed on the car (in case of stage2 or higher).

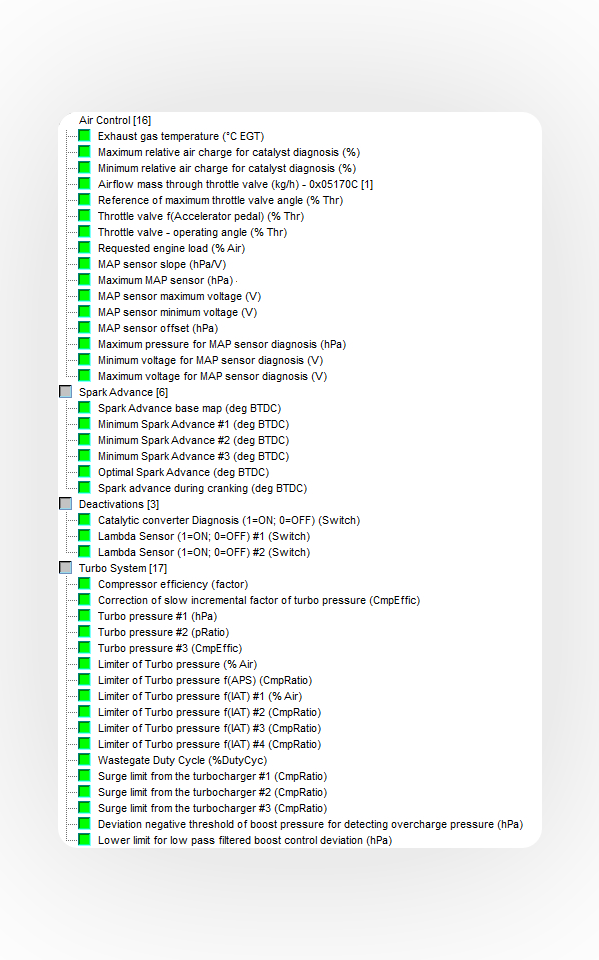

One of the most common modifications on the less powerful T-Jet engines equipped with IHI turbochargers, is to install the sensors of the more powerful versions equipped with Garrett turbines (T-map, T-boost and Pierburg). This allows the engine control unit to have a wider range of parameter reading and therefore allows you to go even further with the performance of your car.

Thanks to the MAF and MAP sensor heating maps and the relative thresholds it will be possible to make the new sensors installed on the engine work correctly!

If the turbocharger is replaced, in this case it will be possible to work on the “Compressor Efficiency” and “Wastegate Duty Cycle” maps (as well as obviously on the other turbo and air load management maps on the driver) in order to recalibrate the flows air and thus allow the engine to run correctly.

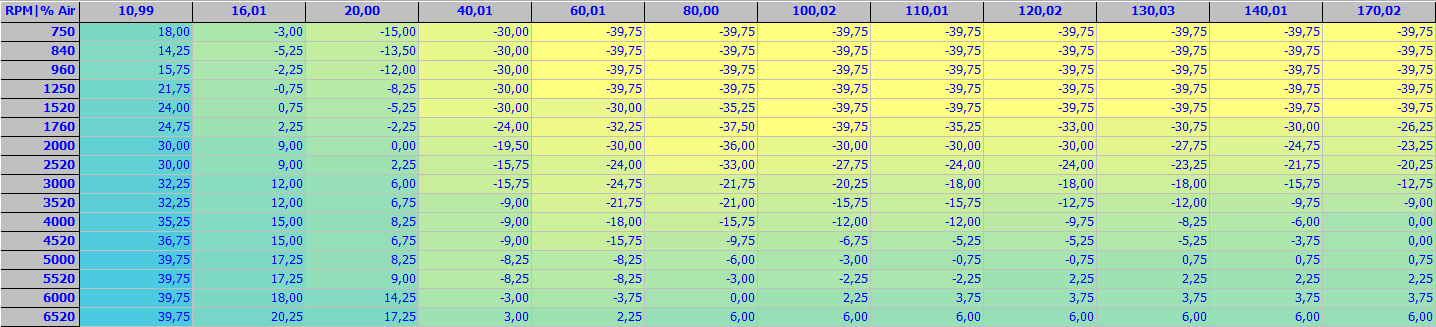

Especially on small Abarths, the Pop & Bang is really in demand. Thanks to the maps present in the ME17.3.0 driver it will be possible to enable this function by managing it with the utmost precision! By working on the release overrun activation maps and on the minimum advance maps, we will have the ability to activate the Pop & Bang at a certain rpm, temperature and for a certain period of time. We found that the best result is obtained by working on the “Delay time for release cut-off activation” maps and on the “Minimum Advance”, “Base Map Advance” and Optimal Engine Advance maps ”.

Using the maps relating to the cut-off activation time, it is possible to define how many revs, at what temperature and after how much to trigger the fuel cut function.

With the advance maps, on the other hand, it is possible to define the engine revolutions and the volume of the Pop & Bang. The greater the angle beyond the TDC, the greater the volume of the exhaust bursts (obviously, remember that the original catalyst could be damaged!)

Please Note. Among the maps that manage the cut-off activation delay there is also a map that is a function of the rpm and the temperature of the catalyst. We believe this map is quite important in order to safeguard the original catalyst, since it gives us the possibility of inhibiting the Pop & Bang after a certain temperature of the catalyst.

BOSCH ME7.9.10

Sport Display Recalibration – ECM Titanium tuning tips

This new major development allows you to work on the Denso GEN IV R7F702002 V35A-FTS ECUs, installed in several off-road Toyota and Lexus models, as well as on 19 other control units, including both ECUs and TCUs.

Operate in all connection modes with 18 new protocols dedicated to the automotive world. This is one of the largest releases for KESS3: now expand your workshop’s intervention capabilities.

Easily and effectively modify engine parameters for several Chevrolet, Holden, and Opel vehicles.

REV limiter – Diesel – ECM Titanium tuning tips