ECM Titanium Case History

The JCB 4CX PRO is designed to handle demanding construction sites, heavy-duty operations, and continuous work cycles. Reliability and versatility are its main strengths, but when the goal is to improve efficiency and engine response, a targeted optimization can make a significant difference—especially during daily operations.

The objective was to reach the higher power level already planned by the manufacturer, improving delivery from low RPM and reducing fuel consumption during the most demanding work phases. A calibrated increase, while preserving the original mechanical reliability.

Thanks to ECM Titanium, the optimization was performed with precision, adjusting the key engine management parameters to fully exploit the potential of the power unit.

The map optimization followed a conservative and goal-oriented approach: achieving a higher torque peak at lower RPM, with an immediate impact on fuel consumption while maintaining the same productivity.

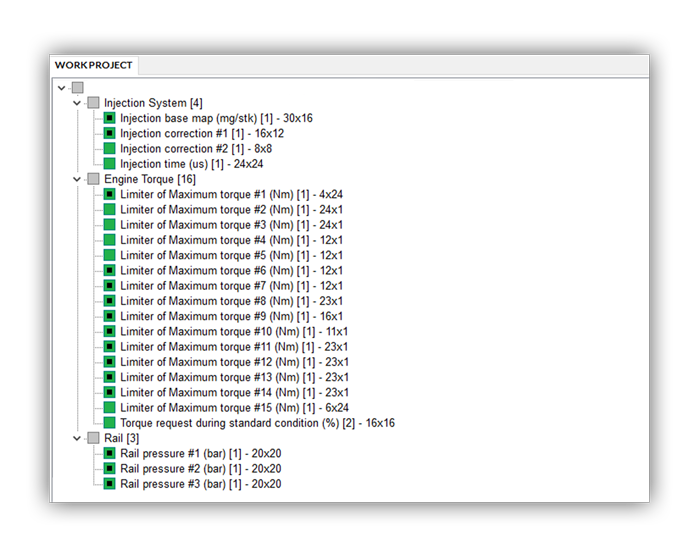

Injection management

A slight increase in injection duration and the injected fuel quantity improved combustion without stressing mechanical components.

Torque limiters

Torque limiters were recalibrated to allow the engine to reach the higher power step, unlocking the potential already foreseen by the manufacturer.

After the intervention, the customer reported a noticeable difference in daily use, with stronger pull under load and smoother control even during extended work sessions.

“It was the first machine in our fleet that we optimized, and the results were visible immediately. After just one working day we could already see the fuel savings. Over a month the benefit became clear, and after a year it’s truly significant.”

Do you want to improve even more in what you do?

Take a look at our training programs worldwide. Invest in your skills and increase your earning potential. A specialist will be with you every step of the way, so you can start working confidently right away!